V1000

Yaskawa has built a reputation for high performance, functionality, quality, and reliability. To make it even easier to optimize your applications, we present the new V1000.

Yaskawa offers solutions customized for your application in an incredibly compact, technologically advanced, environmentally responsible package capable of driving a synchronous motor.

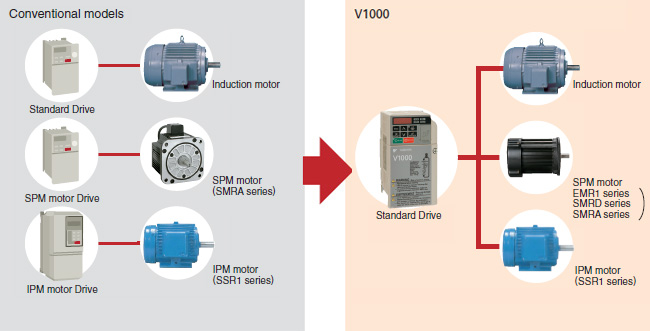

V1000 runs not only induction motors, but synchronous motors like IPM and SPM motors as well. Get a single drive for all your application needs, and save on spare parts.

Note : See product specifications for information on motor precision.

The variable torque ratio of synchronous motors is 1 to 10.

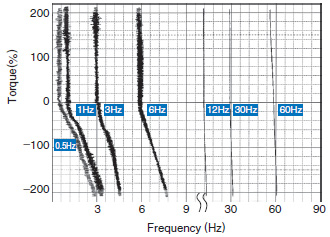

V1000 is the first in its class fully equipped with current vector control. Current Vector control providing a powerful starting torque of 200% at 0.5 Hz∗ and precise torque limit operations. The motor Auto-Tuning function saves valuable start up time and assures high performance operation at the highest efficiency.

∗ : Using a Yaskawa induction motor under 3.7 kW set for Heavy Duty torque performance.

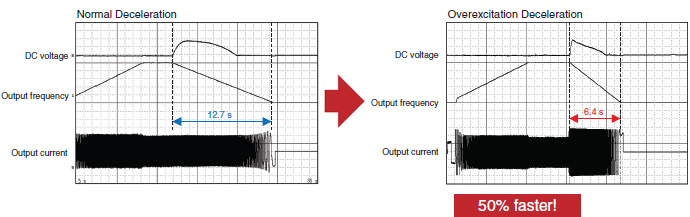

Faster deceleration time with overexcitation braking.∗

∗ : Example shown is for a 400 V 3.7 kW drive without braking resistor.

Circumstances depends on the motor and load.

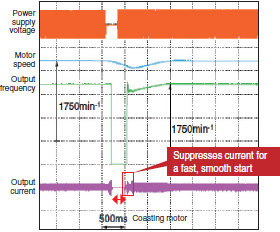

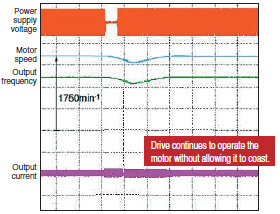

V1000 is fully equipped with speed search and KEB Ride-Thru functions for your application needs, whether running an induction motor or permanent magnet motor.

Speed Search performs smooth restart by finding the coasting motors speed.

Note : Requires a sensor to detect when power loss occurs. Load conditions may still trip a fault and cause the motor to coast.

Yaskawa can offer you a drive with custom software with the specific functions required for your machine.

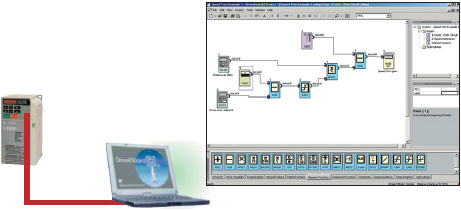

Optional visual programming software lets you instantly customize V1000 to your application. Let the drive do external device or PLC functions! Easy Drag and Drop functions starting from simple timers up to complex application blocks let you create your very own drive.

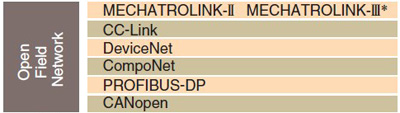

The built in high speed RS-422/485 MEMOBUS and a variety of option units connect V1000 to all popular fieldbus networks. The optional 24 V power supply keeps the drive controller alive under all conditions, providing network communications and monitoring functions even during a main power loss.

Note : The open field network names mentioned are registered trademarks of their respective companies.

Finless design, and dust-proof models also available.

Various products are available to protect your drive against humidity, dust, oil mist, and vibration. Contact Yaskawa for more information.

All V1000 models are fully compliant with the EU's RoHS initiative.

From setup to maintenance, V1000 makes life easy.

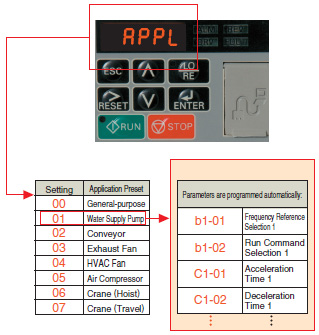

V1000 automatically sets the parameters needed for various applications. Presets for water supply pumps, conveyor systems, exhaust fans, and other applications program the drive instantly for optimized performance-saving enormous hassle setting up for a test run.

Get several drives up and running easily using the USB copy unit. The same copy unit is fully PC compatible.

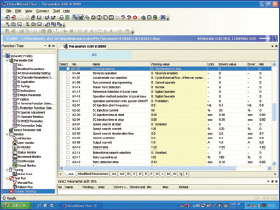

DriveWizard Plus lets you manage the unique settings for all your drives right on your PC.

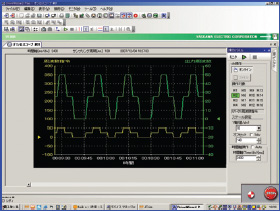

With DriveWizard's preset operation sequences, built-in oscilloscope function, fine tuning the drive and maintenance checks have never been easier.

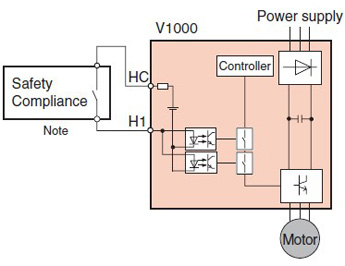

V1000 is the first drive in its class to come standard with safety input features compliant with ISO13849-1 Cat.3 PLd, IEC/EN61508 SIL2.

Through compliance with EN60204-1 (stop category 0), V1000 reduces the number of peripheral devices needed to satisfy safety regulations.

![]()

Note: Output is interrupted 1 ms after the safety input signal is triggered.

Make sure safety input wiring does not exceed 30 m.

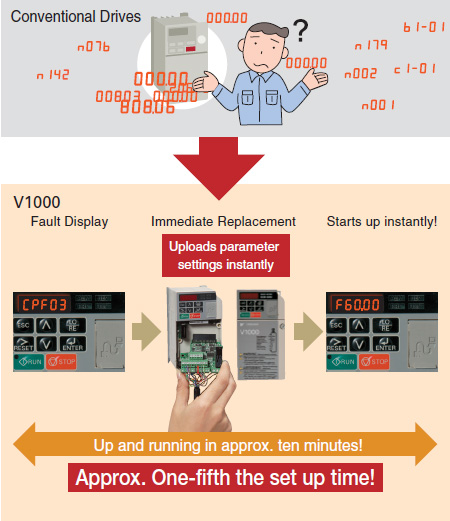

The first-ever pluggable terminal board with a Parameter Back-Up function lets you replace a drive instantly in the event of failure. No need to reprogram the replacement drive-an amazingly convenient time saver!

Cooling fan and capacitors have an expected performance life of ten years. In addition, Maintenance Monitors keep track of part wear.

A pluggable terminal block option is available. Screwless terminals do away with time consuming wiring and periodic maintenance to check wire connections, which in turn makes the drive more reliable. Contact Yaskawa for inquires.

Monitor functions like output frequency, output current, I/O status and watt hour counter give a clear picture of the drive operation status and helps to keep track of the energy consumption.

The Verify Menu lists all setting that have been changed from their original default values. This includes parameters changed by Auto-Tuning, Application Presets, and those edited by the technician. This list makes it easy to reference changes to drive setup.

Top performance for its class. Loaded with functions and features in an unbelievably small package!

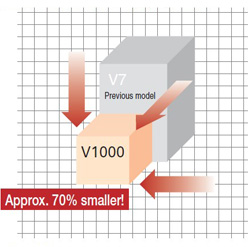

Yaskawa has applied the most advanced thermal simulation technology and top reliability to create the world's smallest compact drive. V1000 reduces the space required up to 70% when compared to our earlier models.

V1000 allows for a truly compact installation, requiring minimal space between units even in a tight enclosure.

Note: If the last drive in a series is installed next to a wall, a 30 mm gap is required.