Do You Have Problems with AC Drives?

Yaskawa's development of the world's first application of matrix converter technology in 2006 made it possible to solve AC drive problems. Further evolution of this technology has resulted in the U1000.

This sophisticated series of motor drives available only from Yaskawa eliminates the problems of standard AC drives.

The U1000 tops the performance of general-purpose AC drives to further improve the performance of your facilities.

When a motor rotates, it consumes energy. When a motor is rotated, it generates energy.

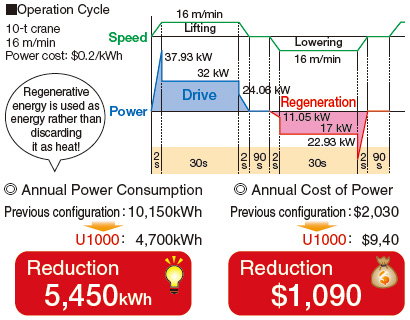

You can save energy by using regenerative energy instead of wasting it.

Braking resistor results in discarding energy as heat,but you can return this regenerative energy to the power supply to save energy.

Example of the Effectiveness of Regenerative Energy Savings

Use analog outputs or communications networks to monitor all sorts of data with easy operations. You'll instantly see the energy that you've saved.

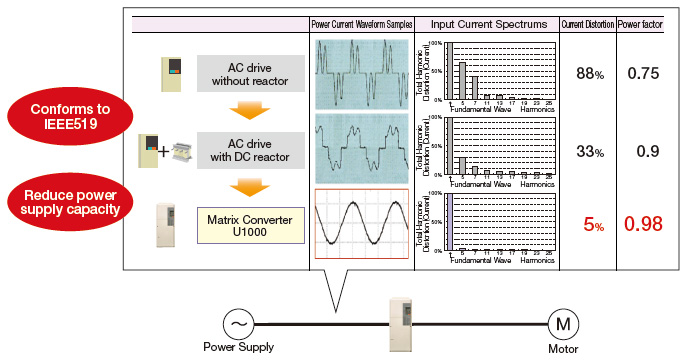

Without peripheral devices, the input current waveform becomes sinusoidal, similar to that of a commercial power supply, so the harmonic pollution of the power supply is minimized for the protection of surrounding machinery. The available power system capacity can be increased, and the regulations on harmonics easily met.

When an AC drive converts power, the input current is distorted, which results in harmonics.

These harmonics can interfere with other electric devices, such as by causing overheating or damage to power supply facilities and malfunction and noise in precision devices.

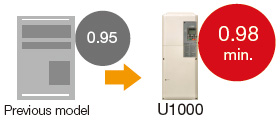

The power factor is high, so you can use a lower power supply capacity.

You can also downsize wires and generator capacity, and may qualify for price benefits from your power company.

Harmonic countermeasures that were previously required to connect a converter, such as input AC reactors, harmonic filter reactors, and capacitors, are not necessary, which helps you save wiring, space, and energy costs.

.jpg)

When a motor rotates, it consumes energy. When a motor is rotated, it generates energy. You can save energy by using regenerative energy instead of wasting it.

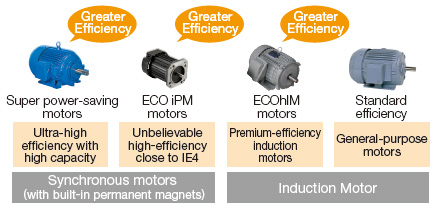

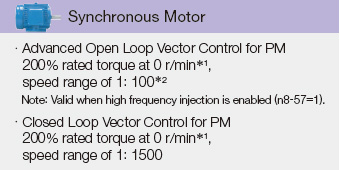

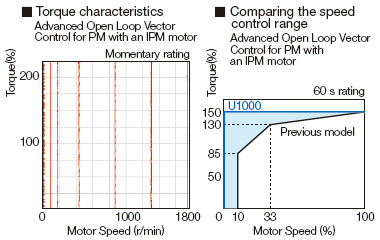

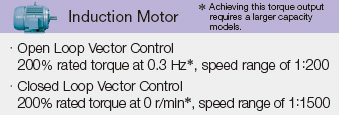

All types of motors can be controlled, including induction motors and IPM/SPM synchronous motors, without using sensors.

We've increased the number of 200-V-class models from 4 to 10 and the number of 400-V-class models from 7 to 23.

The high power factor allows you to reduce the power supply capacity.

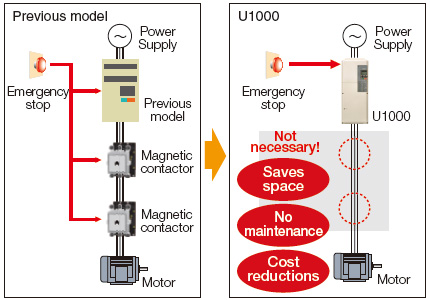

SIL3 compliance eliminates the need for magnetic contactors (MCs).

Output frequencies are supported up to 400 Hz.

Models are available with built-in EMC noise filters to reduce noise generated by AC drives.∗

∗ Be sure to use a stand-alone EMC filter for models

CIMR-U*4*0477 to 4*0930.

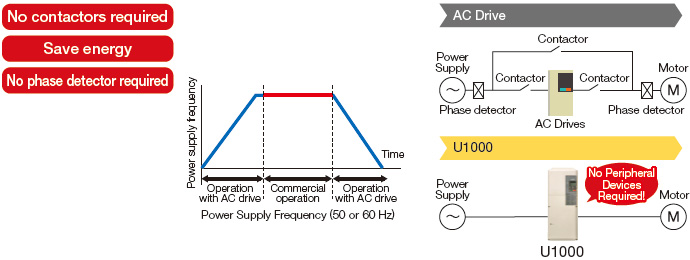

Switching to and from commercial power is possible without phase detectors, contactors, and other such peripheral devices.

Note V/f control without a PG must be used.

A built-in 24-V power supply unit lets you check parameters even when the main circuit power supply is OFF.

A speed response of 250 Hz∗ enables rapid following of AC drive frequency references.

∗ Closed-loop vector control, Closed-loop vector control for PM

• Powerful torque at 0 Hz even without the use of a motor encoder.

Powerful torque at 0 Hz even without the use of a motor encoder. Achieve even more powerful starting torque at zero speed with an IPM motor.

∗ No speed sensors or pole sensors required.

∗1 Achieving this torque output requires a larger capacity models.

∗2 Contact your Yaskawa or nearest agent when using PM motors except SSR1 series or SST4 series motors manufactured by Yaskawa Motor Co., Ltd

• High-performance current vector control achieves powerful starting torque with an induction motor.

• Protective Design

A variety of protective designs are available to reinforce the drive against moisture, dust, oil mist, vibration, corrosive sulfur gas, conductive particles, and other harsh environments.

• RoHS

All standard products are fully compliant with the EU’s RoHS directive.

![]()

Be sure to use a stand-alone EMC filter for models

CIMR-U*4*0477 to 4*0930.

• Safety Regulations

The products comply with ISO/EN13849-1 Cat.3 Ple and IEC/EN61508 SIL3 (two safety inputs and one EDM output).

An External Device Monitor (EDM) function has also been added to monitor the safety status of the drive.

Compliance with SIL3 decreases the malfunction rates and creates a safety system.

When compliant with EN81, the number of required magnetic contactors, which has conventionally been two, can be reduced using the safety function.

Crane and elevator applications are available.

• DriveWorksEZ visual programming tool with all models

Simply drag and drop icons to completely customize your drive.

Create special sequences and detection functions, then load them onto the drive.

• Program a customized sequence

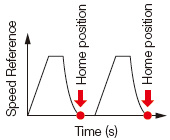

Example : Positioning control without a motor encoder

• Create customized detection features

Example: Machine weakening analysis using torque fluctuation detection

• USB for connecting to a PC

USB port lets the drive connect to a PC

Drives are also equipped with an RJ-45 comm. port that takes

the existing WV103 cable used in Yaskawa’s previous models.

Simply remove the operator keypad for to the RJ-45 connector.

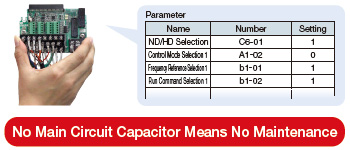

• Removable Terminal Board with a Parameter Backup Function

The terminal block’s ability to save parameter setting data makes it a breeze to get the application back online in the event of a failure requiring drive replacement.

• Parameter Copy Function

All standard models are equipped with a Parameter Copy function using the keypad that allows parameter settings to be easily copied from the drive or uploaded for quick setup.

A USB Copy Unit is also available as an even faster, more convenient way to back up settings and instantly program the drive.

• Engineering Tool DriveWizard Plus

Manage the unique settings for all your drives right on your PC.

An indispensable tool for drive setup and maintenance. Edit parameters, access all monitors, create customized operation sequences, and observe drive performance with the oscilloscope function.

U1000 has been awarded with 4-Ticks (Leader) in the Singapore Green Building Product Certification 2018.