The world’s highest speed performance

The DX200 new robot controller brings out the maximum performance in speed and torque from the new servomotors on the robot’s axes and increases the motion speed of each robot’s axis. This greatly reduces the cycle time in various applications.

The slimmer structure, new features and high performance enable you to downsize production facilities and save energy.

HARDWARE

Best Performance in its class

The highest speed in the world has been achieved by using high-speed, low- inertia AC Servomotors and state-of-the-art control technology. A slimmer robot form has also been developed, while wrist allowable inertia has been increased.

Applicable in Severe Environment

The waterproof and dustproof structure (IP67 class level)*¹ at the wrist part enables the robot to operate in environments subjects to waterdrops and dust. *1: Available as an option for MH5S, MH5LS,MH6 and MH6S

DX200 Controller

Dynamic Energy-efficient multiple Robot Controller

|

| SOFTWARE |

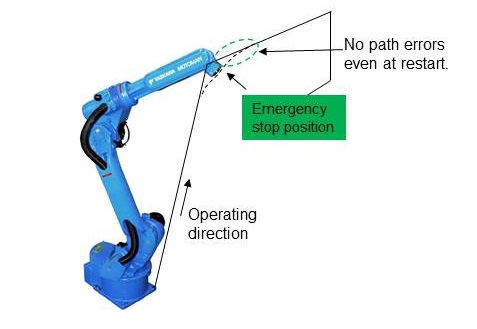

No Deviation from Track at Emergency Stop

The Robot stops on the taught path at emergency stop and will deviate from the path when restarting, preventing interference of the Robot with nearby obstacles.

Playback path confirmation

The playback path mode during a test operation can be confirmed by low speed test operation. This mode of teaching operation with the optimum path in minimal time possible while verufying the existence of interference with workpieces or jigs.

Interference Checking Function (Optional)

Interference between arms of densely installed Robots can be constantly monitored to automatically stop movement if a collision is likely to occur. (This prevents collisions between Robots caused by programming mistakes.) Constantly checks the interference between the robot arm ad up to 16 defined cubes to prevent the robot to collied with workpieces or peripheral jigs.

Minimized Safety Barrier(Optional)

The functional safety unit , which is configured with the redundant CPUs minimizes the area within the safety barrier by restricting the robot's operating area.

•Safety barrier can be limited to only a minimum area to downsize production facilities

•Zone limit switches can be eliminated for Robots in setting process.

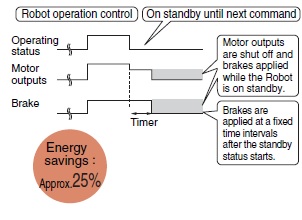

Saving Energy

The servos are turned OFF automatically when the Robot is stopped for long period of time. Twenty four hour operation in which Robot is operating for 16 hours and on stand by for 8 hours

Operability of teaching and simulation have been improved to reduce time required for system start up.

Multi-window Display Function

Programming operation can be checked while monitoring I/O or variables on the programming pendant so that teaching and trial operation efficiency will increase.

MotoSimEG-VRC Simulator (optional)

The Simulator has evolved from merely simulating Robot operation to a virtual Controller that reproduces the function, operations and displays of the actual Robot. Easy simulation is possible by anyone with an understanding of Robot operation.

Motoman continually strives to improve monitoring, troubleshooting and structures to reduce maintenance and recovery time from failures.

Troubleshooting

When an alarm occurs, the detail, cause and countermaeasure of the error are displayed on Programming Pendant to provide measures of troubleshooting.

Reduced Replacement Time for Parts

We have reduced the time required to replace Controller parts to shorten recovery time when troubles occur. (Required time for replacement: from 10 to 8 minutes reduced by 20%)

The encoder can be replaced with standard tools since it employs a unit style and thus the required time for replacement is reduced.

An optional zeroing function can be used to accrurately and quickly reset the home position after replacing the motor or encoder.