Ultimate system performance

The high-performance of Σ-7 SERVOPACKs translates into ultra-high-speed and ultra-high-accuracy control, which maximizes system performance.

Σ-7S Single-axis SERVOPACKs

3.1 kHz response frequency

3.1 kHz response frequency

Optimized for specific applications: New models in EX and FT series to be released

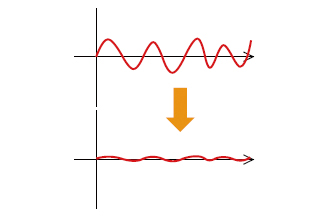

Improved vibration suppression

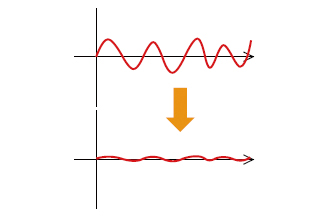

Ripple compensation

Σ-7 SERVOPACKs can reduce speed ripples caused by motor cogging, even for machines for which speed loop gains cannot be set high. This ensures smooth operation.

Enhanced vibration suppression function

- Notch filter

Suppresses high-frequency vibrations of 500 Hz or higher.

⇒Number of filters increased from 2 to 5.

- Anti-resonance control adjustment

Suppresses vibrations at frequencies ranging from several hundred Hz to 1 kHz.

⇒Vibrations can now be suppressed at two different frequencies (in comparison with one frequency in earlier models).

- Vibration suppression

Suppresses vibrations at low frequencies (30 Hz and lower).

⇒Vibrations can now be suppressed at two different frequencies (in comparison with one frequency in earlier models).

These functions can be adjusted automatically using the autotuning function.

Σ-7W 2-axis SERVOPACKs

|

2-axis SERVOPACKs (200 W × 2 axes to 1 kW × 2 axes)

3.1 kHz response frequency

Improved vibration suppression

|

Σ-7 Servomotors

|

Compact dimensions (approx. 80% smaller than our earlier models.)

High-resolution 24-bit encoder incorporated (16,777,216 pulses/rev)

Maximum torque: 350% (small capacity)

|

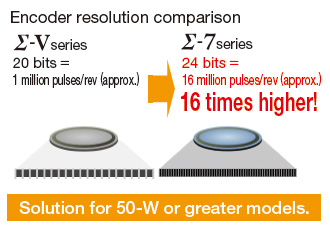

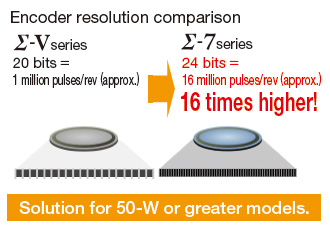

High-resolution, 24-bit encoder

Σ-7 Servomotors (50 W or greater) use encoders with a resolution that are 16 times higher than those used in Σ-V Servomotors.

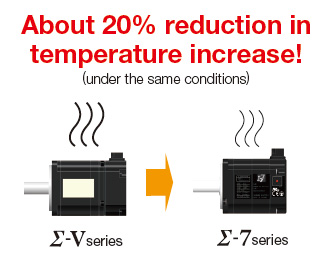

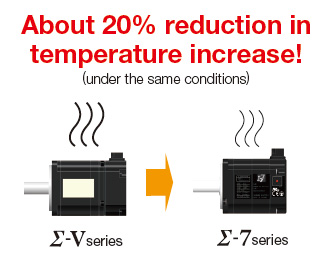

High efficiency and low heat generation

Σ-7 Servomotors use an optimized magnetic circuit that improves motor efficiency and reduces heat generation.

(comparison with typical models.)

Ultimately ease to use

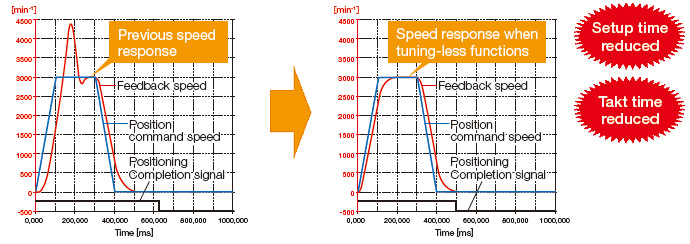

Yaskawa's original tuning-less function has undergone further development.

Stable operations can be achieved without having to adjust gains.

No need to adjust servo gains

With Yaskawa's original tuning-less function, systems can run without vibration for a load with 30 times (max.) of load moment of inertia. Systems remain stable even with load changes during operation.

| |

Σ-V Series |

Σ-7 Series |

| Allowable load moment of inertia ratio |

30 times (max.) |

30 times (max.) |

| Max. control gain |

Speed loop gain

40 Hz (approx.) |

Speed loop gain

70 Hz (approx.) |

When the allowable load moment of inertia ratio is 30 times:

Ultimate environmental performance

The Σ-7 Servo Drives can be used in harsh environments and conserve energy.

Optimal systems can be easily set up in different countries and under a variety of conditions.

Satisfies specifications for use overseas and in harsh operating conditions

- 240 VAC supply voltage also supported

- High-altitude use increased to 2,000 meters above sea level∗

- Maximum ambient temperature raised to 60?∗

- ∗ : Derating required.

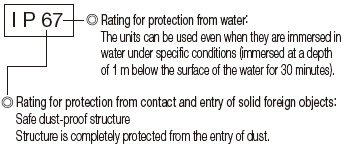

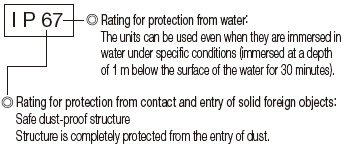

Waterproof protective structure upgrade to IP67 rating

SGM7A (IP22 for 7.0 kW), SGM7J and SGM7G models

Protective Structure (IEC 144, 529, DIN40050, JEM1030)

Ultimate safety and security

Systems can be operated safely because the Σ-7 Servo Drives comply with safety standards and safety is ensured by monitoring.

Satisfies requirements of the SIL 3 of the IEC 61508 functional safety standards∗ (first in Japan) ∗: Certification scheduled for April 2014

Certification will make it easier to set up systems that conform to safety standards for press machines and other systems in Europe and other regions. Certification also helps reduce the number of hours required for wiring and of peripheral devices.

Complies with Stop Category 0 (Safe Torque Off)

| |

Safety standards |

Performance level & category |

| Safety of machinery |

EN ISO13849-1 |

PLe (CAT3) |

| IEC 60204-1 |

Stop Category 0 |

| Functional safety |

IEC 61508 |

SIL 3 |

| IEC 62061 |

SIL CL3 |

| IEC 61800-5-2 |

STO |

- The safety function works even for a single problem.

- The safety function is enhanced with compliance with the EN ISO 13849-1 PLe

(performance level e).

| Note : |

Although the safety performance level of the Σ-V series Servo Drives is PLd (performance level d), the benefits described in the figure on the left apply. |

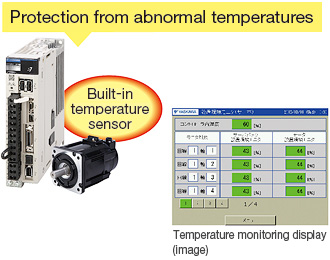

Protect systems from high temperatures

Σ-7 SERVOPACKs and Servomotors are equipped with temperature sensors that can directly monitor temperatures of machines and detect abnormalities to prevent failures. Real-time temperatures can be viewed on a display by using Machine Controllers.

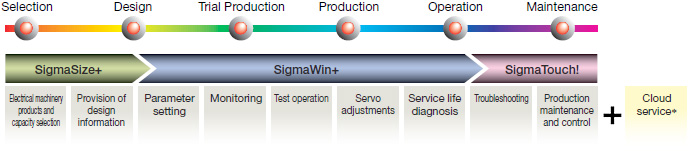

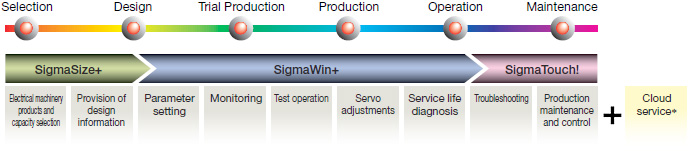

Ultimate support

Cloud-based storage of product data facilitates data retrieval when needed.

Maintenance throughout a product's service life is improved and simplified with SigmaTouch!∗, Yaskawa's smartphone application.

- ∗ : Starts in spring 2014

-

Single or multiple orders possible after specifying parameters

Customers can now place single or multiple orders for SERVOPACKs in the Σ-7 series after specifying parameters at the factory shipment stage. No longer is it necessary to write the parameters at the system assembly site, which means that production lead times can be reduced.

Product management and maintenance service

- Manufacturing information of each product can be easily viewed by using SigmaTouch!, Yaskawa's smartphone application. To view, simply hold your smartphone over the QR code of the product.

- With SigmaTouch!, you can access the serial numbers of products installed in systems, and manage the information in the MechatroCloud on a system-by-system basis.

- SigmaWin+ supports MechatroCloud.

After a product has been adjusted, its parameters, trace data, and other information can be kept in the MechatroCloud on a system-by-system basis.

Features

Simply access the MechatroCloud service∗ and hold your smartphone over the QR code of the product. You can access the product data stored in the MechatroCloud, and view the manual for that product.

- Note: MechatroCloud is a new cloud service provided by the Yaskawa Electric.

Improve troubleshooting

- If you have a smartphone, troubleshooting information can be accessed by reading a product's QR code.

- Automatic tracing is possible when a SERVOPACK alarm occurs. This allows you to detect and solve problems promptly.

Planned maintenance now available by monitoring the operational status

The service life of the maintenance can be estimated, and the users are notified when the parts should be replaced. System failure can be prevented because parts can be replaced before products break.

Display for total hours of use and remaining service life (image)

Ultimate Lineup

You can construct a system that exactly meets your requirements using communications networks and the rich lineup of products offered by Yaskawa's partner companies.

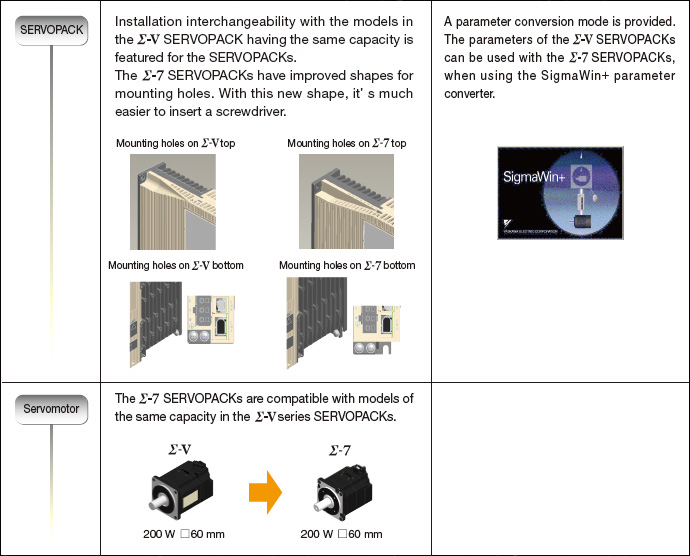

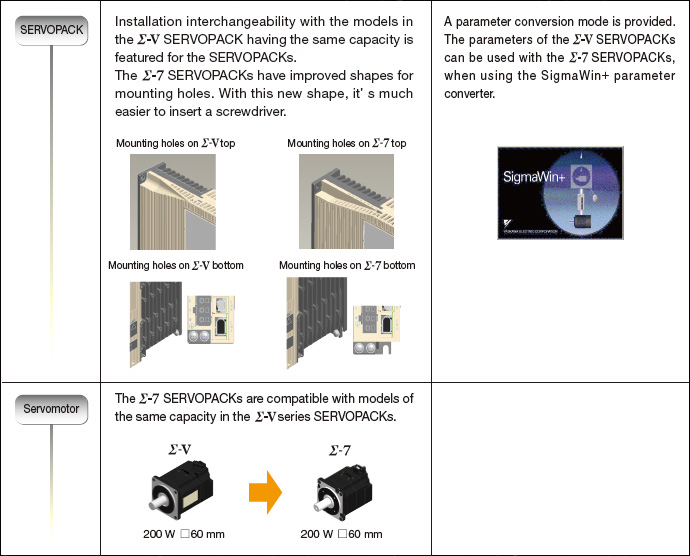

Ultimate compatibility

Compatibility with earlier series is assured. You can improve the performance of your system by replacing devices currently used with Σ-7 Servo Drives.

3.1 kHz response frequency

3.1 kHz response frequency